Choosing the Right Valve Connection

In industrial piping systems, the choice of valve connection has a significant impact on system performance, reliability and maintenance costs. Different scenarios have different requirements, and reasonable selection can ensure efficient operation of the system and prevent leakage and other problems.

Let's take a look at the common valve connection methods and their applicable scenarios as follows:

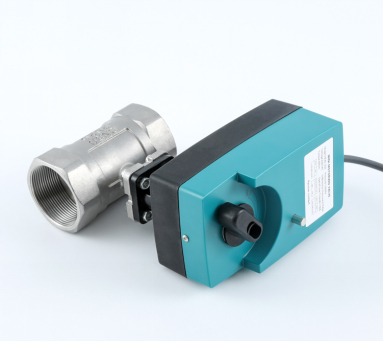

1.Threaded Valve

The screw connection is simple, the valve end is processed into conical pipe or straight pipe thread, and can be connected to conical pipe thread joints or pipelines, which are often used for valves with nominal diameters below 50mm. Because the connection part is easy to leak, sealant and other AIDS are often needed. When the material of the valve body is weldable but the expansion coefficient difference is large or the temperature change is large, the connection part should be sealed and welded.

Threaded valves are easy to install and low cost, suitable for pipelines with low pressure and temperature requirements and small diameter, such as water supply and drainage pipelines in buildings. However, the diameter is too large, the installation and sealing difficulty will increase.

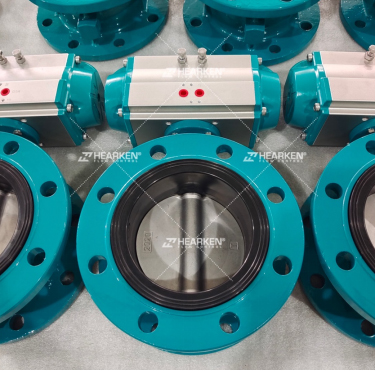

2.Flanged Valve

The valve connected by flanges has flanges at both ends and is bolted to the pipe flange for easy installation and disassembly. Compared to threaded connections, it is bulkier and more expensive, but suitable for various sizes and pressures of pipe.

There are many kinds of flange joint surface, such as smooth type and convex type. Smooth type for valves with low pressure. However, when the temperature exceeds 350 degrees, bolts, gaskets and flanges are relaxed by heat, which is easy to leak. Flanged valves are suitable for industrial pipelines with high installation and disassembly requirements and a wide range of pressure and temperature, such as petrochemical and power industries.

3.Welded Valve

Welded connections are suitable for a variety of pressures and temperatures, and are more reliable than flange connections under harsh conditions, including butt welding and socket welding. The two ends of the valve body are processed into grooves and welded with pipes during butt welding. Socket welding is used for nominal diameter of 50mm below the valve, the valve body end has a socket to undertake the pipeline, but because the gap is easy to corrosion, vibration fatigue, the use is limited. Bevel butt welding is often used in large diameter, harsh working conditions and high temperature occasions, and the requirements for welds are high.

It is difficult to disassemble and reinstall the welded connection valve after installation, which is mainly used for long-term reliable operation or harsh working conditions, such as the pipelines of thermal power stations, nuclear energy projects, ethylene projects, and its connection is firm and its sealing is good, but it is inconvenient to repair and replace.

4.The Sleeve Connects the Valve

The sleeve connection is sealed by tightening the nut, so that the blade of the sleeve bites into the outer wall of the pipe, and the outer cone is close to the inner cone of the joint. It is small in size, light in weight, simple in structure, easy to disassemble and assemble, strong in connection, resistant to high pressure (1000 kg/cm2), high temperature (650℃), impact and vibration, can choose a variety of materials to prevent corrosion, processing accuracy requirements are not high, easy to install at high altitude.

5.The Wafer Connection Valve

The valve connected with the clamp is installed in the middle of two flanges, the valve body has a positioning hole for easy installation, and the valve and the pipeline are clamped together with bolts. This connection has compact structure, small space, easy installation, suitable for the limited space of the pipeline system, often used in butterfly valves, check valves, and widely used in water supply and drainage, HVAC fields. However, the concentricity of the pipeline is required to be high, otherwise the sealing performance will be affected

6.The Clamp Connects the Valve

Clamp connection only two bolts, easy to operate, suitable for low-pressure valves that often need to be disassembled, can be quickly installed and disassembled, saving time and manpower, such as food and beverage industry pipelines. However, the sealing performance is relatively weak, and it is suitable for pipelines with low pressure and non-dangerous media.

Summary

You can find that choosing a valve connection way to comprehensive consideration of various factors, accurate selection according to the specific scene, can ensure that the valve in the pipeline system is stable and reliable in operation, and the security of industrial production.