The Difference Between Double Acting and Spring Return Pneumatic Actuators

What Do DA and SR Mean in Pneumatic Actuators?

In pneumatic actuators, DA (Double Acting) and SR (Spring Return) are common terms that refer to two distinct actuator types.

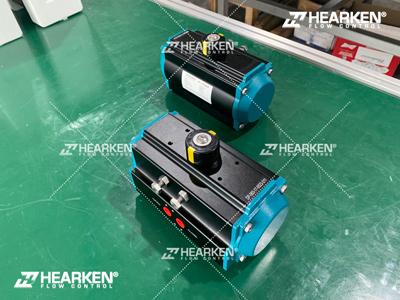

DA (Double Acting) Pneumatic Actuators

DA stands for Double Acting, which indicates that the actuator has two chambers but no internal spring.

How Double Acting Pneumatic Actuators Works:

In a double acting actuator, compressed air is directed into either of the two chambers, causing the piston to move back and forth. This movement controls the opening and closing of valves or other devices.

For example:

- When air is supplied to one chamber, the piston moves in one direction, opening the valve.

- When air is supplied to the opposite chamber, the piston moves in the opposite direction, closing the valve.

- Both valve opening and closing require an external air supply.

What are the characteristics of Double Acting Pneumatic Actuators?

High force output and fast action are some of the key benefits of double acting actuators.

They are ideal for situations that demand fast valve operation and significant force, such as controlling ball valves, butterfly valves, and similar devices in large industrial pipelines.

DA Pneumatic Actuators Applications:

Commonly used in industries like oil, chemical, and power generation, where high precision and quick response are crucial.

SR (Spring Return) Pneumatic Actuators

SR stands for Single Acting with Spring Return functionality.

How Spring Return Pneumatic Actuators Works:

A spring return actuator operates with a single air chamber and uses a spring to automatically return the piston to its original position when air pressure is not applied.

The operation works as follows:

- When air is supplied, the piston moves, either opening or closing the valve.

- When the air supply is lost, the spring automatically pushes the piston back to its default position, either open or closed, depending on the actuator’s configuration.

- For instance, in a fail-safe application, a normally open spring return actuator will close the valve when there is air pressure and open the valve when the air supply fails.

What are the characteristics of SR Pneumatic Actuators?

Simple design and cost-effective with the added advantage of fail-safe operation (returns to a predefined position when air pressure is lost).

SR Pneumatic Actuators Applications:

Often used in systems that require a specific valve state for safety, such as fire safety systems, where valves must automatically open in case of air supply failure to ensure water flow.

Common in smaller pneumatic control systems or cost-sensitive applications.

Key Differences Between Double Acting and Spring Return Pneumatic Actuators

The primary differences between DA and SR actuators lie in their operating mechanisms and ideal use cases:

DA actuators require an external air supply for both valve opening and closing, providing high force and fast action suitable for large industrial applications.

SR actuators, on the other hand, use a spring to return to the default position, making them simpler, more economical, and suitable for systems requiring fail-safe operations.

How to Choose Between Double Acting and Spring Return Pneumatic Actuators?

When selecting between a double acting (DA) actuator and a spring return (SR) actuator, it’s essential to consider the following:

Best Choice for High-Speed, High-Force Applications: Double Acting Actuators

For high-speed, high-force applications, especially in large industrial systems, DA Pneumatic actuators are the best choice. They offer superior power and quick valve actuation, which is necessary for complex systems in industries like oil, chemicals, and power generation.

Ideal for Safety-Critical Applications: Spring Return Actuators

For safety-critical applications that require a valve to return to a predefined position in the event of air supply failure, SR actuators are ideal. They are widely used in fire safety systems, small control systems, and cost-sensitive applications.

Why Single Acting Actuators are Preferred for Safety and Cost-Effectiveness?

Given the simplicity, low cost, and fail-safe features of spring return actuators, they are often preferred in applications where operational safety is a top priority.

FAQs

Q: What is the difference between "air source overcomes spring output torque" and "spring output torque"?

A: The former is the torque that needs to overcome the spring's own torque and then output when the single-acting air is opened; the latter is the torque output by the spring when closed when there is no air.

Q: Can HPA pneumatic actuators use compressed nitrogen to supply air to the actuator?

A: No, it will freeze when it is pumped in.

Q: If more springs are installed on the pneumatic actuator, does the actuator have a large torque to open a larger valve?

A: Yes

Q: What is the degree of the pneumatic actuator opening?

A: 90°