Triple Eccentric Butterfly Valve

Let's begin with the "triple eccentric butterfly valve" to show how a fundamental principle works. The butterfly valve's valve body has a transverse valve port (a valve diameter) attached to the pipe that goes through the valve. This valve port is connected to the line that goes through the valve. Perpendicular to the valve port, the shaft goes through a valve protected by a plate when it is done. On the outside of the valve plate, there is a spherical surface.

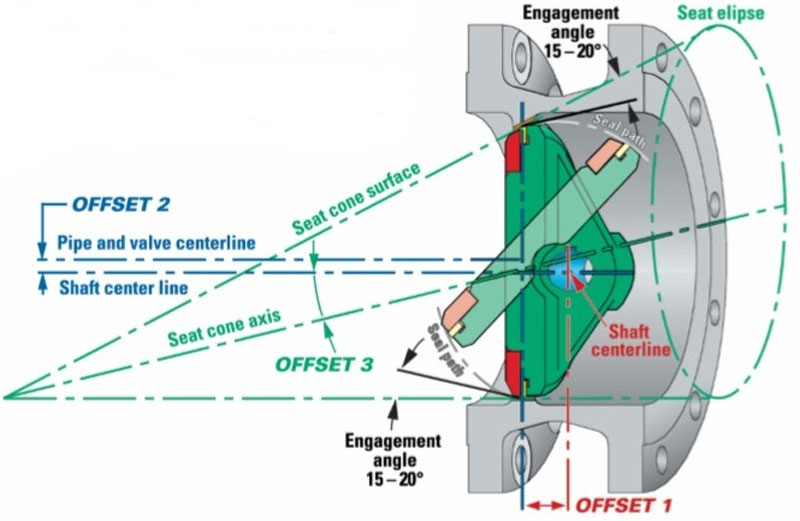

However, when it comes to the valve port, it also has a sealing surface that could work with the outside spherical surface, which is a strange distance between the centerline of the rotating shaft and the centerline of each side of the valve's lateral centerline, which means a gap between these two points. This gap is called "three-eccentric."

This valve works by making an angle between the connection line of the outer spherical surface and its connection line to the valve port.

With its structure principle, it manufactures large-diameter valves, oil pipelines, steel plants, gas lines, catalysis and cracking, ethylene oxide, polyethylene, polypropylene, and other media regulation and cutting devices, as well as other media regulation and cutting devices. Because of how it works, we can also use it

for water purification. Cooling water systems in various industries, including thermal power plants and natural gas, as well as lye, seawater, acid, and other acids, are used to cool down the system. It is also used in the military to cool down water systems that must keep at a high temperature for long periods.

When utilized in applications where the temperature is low, such as liquid oxygen, liquid nitrogen, and other liquids, PTFE-based valve covers and seats are preferred. The temperature varies from -183 degrees Celsius to 196 degrees Celsius (as measured in degrees Celsius).

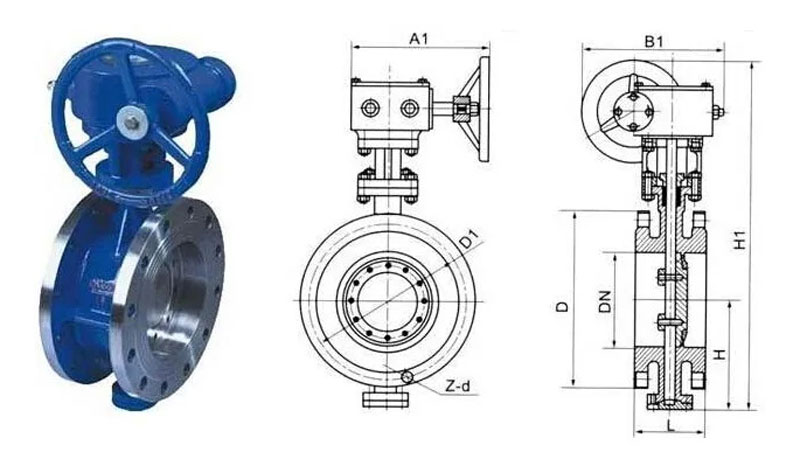

There are only a few parts in the butterfly valve design: simple to build, small in size, and light in weight. Another good thing about the valve is that it is easy to use, requiring a 1.5-degree turn to open and close it quickly.

For a butterfly valve to close, its shaft must be moved by force. This causes pressure to build up between its outer spherical and sealing surfaces. When the butterfly valve is completed, the tension between its outer spherical surface and its sealing surface is caused by the torque applied to its shaft. This causes the valve to close.

As a result, it is possible to create regulated contrast pressure and improve the sealing performance of the triple eccentric butterfly valve when combined with the elastic compensation of the Mtype adjustable valve seat. This results in a significant increase in the service life of the valve.

Because it can move the shut-off element in two different directions, the regulating valve can be divided into two separate strokes depending on its orientation. The two sorts of strokes are straight and wavy. Straight strokes are the more common

When the shut-off element (such as the spool or valve plate) moves in a rotating direction through the liquid medium, the valve is said to be operating with an angular stroke. On the other hand, when the shut-off element (such as the spool or valve plate) hauls in a straight line, the valve is said to be in straight-stroke mode.

Straight stroke valves have a complicated medium flow channel with an S-shape. Because of this, the medium flow channel has a high flow resistance and a low flow capacity, which means that the Kv value for the medium flow channel is shallow. As a result, they cannot be closed or opened. As a result, the core of the valve can't be completed or opened, and the size and weight of the valve are both immense and very heavy compared with the valves they are meant to replace.

When the valve core moves up and down, it's easy for the medium to get out, and the sealing isn't excellent. The pressure difference that can tolerate is also slight because the valve core moves up and down. However, erosion and cavitation can also happen when there is a big difference in pressure between the two sides.

As a result of the flow channel's angular stroke medium flowing through it, the flow resistance is minimal. This indicates that the flow capacity is significant and that the flow rate is high. Precipitation is also tricky with this media. This is because the angular stroke medium flow channel is relatively straightforward.

Furthermore, the internal cavity and form may be observed because the flow channel is straightforward. In addition, the overall size is maintained to a bare minimum. After examining a large number of various valves, it becomes evident. The angular-strike valve will soon surpass all other types of regulator valves in terms of popularity.

Angle-stroke valves come in a variety of shapes and sizes. However, the ball valve, the butterfly valve, and the three-eccentric triple eccentric butterfly valve are three of the most common (also known as the triple eccentric butterfly valve).

When determining the quality of a valve, there are a variety of considerations to explore. Some features include adjustment, cut-off, differential pressure, anti-blocking, corrosion resistance, pressure resistance, temperature resistance, weight, appearance, and external leakage (if applicable).

The triple eccentric butterfly valve is the only valve that can meet all of the above requirements. It is not recommended because of a ball valve's weight, volume, and appearance. A standard butterfly valve is difficult to stop fluid flow and has a lot of torque; the triple eccentric butterfly valve is the only valve that can meet all of the above requirements.