A Brief Guide To Valves

This introduction of valves is mainly aimed at people who are encountering this product for the first time, and the content is simple and easy to understand.

What’s the Definition of Valve?

A valve is a mechanical device used to control the flow of fluids, such as gases, liquids, and slurries. It's widely applied in various industrial and daily - life scenarios. It can open or close pipelines, regulate the flow rate, control the flow direction, prevent backflow, and more.

The History of Valves

The history of valves is long and rich. Around 2000 BC, the Chinese used wooden plugs and bamboo tubes to control water flow. In ancient Egypt, similar wooden cocks were used in water conservancy projects. During the Middle Ages, bronze and iron valves were used in the water supply systems of European cities. The Industrial Revolution brought crucial changes. The steam engine led to the emergence of various valves such as slide valves, globe valves, and gate valves. After World War II, with the development of materials, ball valves, diaphragm valves, etc. rose rapidly, and valve manufacturing became an important part of the machinery industry. In the 21st century, valves have been advancing towards intelligence and automation.

The Main Material of Valves

The main valve material types are as follows:

Metal Materials

Cast Iron: Low - cost, good wear - resistance and high compressive strength, but poor toughness. Commonly used in valves for normal - temperature and low - pressure media like water and sewage.

Cast Steel: Good strength and toughness, can withstand high pressure and temperature. Widely used in industrial pipeline valves for media such as steam and oil products.

Stainless Steel: Features good corrosion - resistance, high - temperature resistance and hygiene. Suitable for fields like chemical, food and pharmaceutical industries with high corrosion - resistance requirements.

Copper and Copper Alloys: Excellent thermal conductivity, corrosion - resistance and good workability. Often used for low - temperature and low - pressure media like water and gas, such as household heating valves.

Non - metal Materials

Plastics: Offer advantages like corrosion - resistance, wear - resistance, light weight and low cost. Valves made of PVC, PPR, etc. are commonly used in pipelines for corrosive media in water supply/drainage and chemical industries.

Ceramics: Have extremely high corrosion - resistance, wear - resistance and high - temperature resistance, but are brittle. Suitable for special occasions with strong corrosion, high temperature and high cleanliness requirements.

Composite Materials

Steel -lined Fluoroplastic: Combines the strength of steel and the excellent corrosion - resistance of fluoroplastic. Used in industries with strongly corrosive media, such as chemical engineering and electroplating.

Rubber - coated Metal: Utilizes the flexibility and sealing of rubber along with the strength of metal. Commonly used in valves requiring good sealing and shock - absorption, like soft - sealed butterfly valves.

List of Valves: Different Types of Valves

Here is a list of valve types:

- Gate Valve: The closing part is a gate plate, moving perpendicular to the fluid flow. It's for cutting off media and can only be fully open or closed.

- Globe Valve: Relies on valve - stem pressure to make the valve disc fit the valve - seat sealing surface, used for cutting off, regulating, and throttling.

- Plug Valve: The closing part is plunger - shaped. It rotates 90° to open or close the passage, with a simple structure, quick operation, and low fluid resistance.

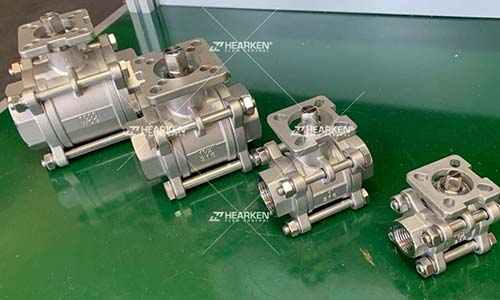

- Ball Valve: Uses a sphere with a circular passage as the closing part. The sphere rotates around the valve - stem axis for opening and closing, featuring good sealing, small size, and easy operation.

- Butterfly Valve: The closing part is a disc that rotates around the valve shaft for opening and closing, mainly for cutting off and throttling in pipelines.

- Diaphragm Valve: Uses a diaphragm as the closing part, opening and closing by the diaphragm's up - and - down movement. Suitable for corrosive and particle - suspended media.

- Check Valve: Prevents medium backflow, with types like lift - type, swing - type, and butterfly - type.

- Safety Valve: Automatically opens to release excess medium when the system is over - pressured, protecting system safety. Types include spring - loaded, lever - type, and impulse - type.

- Control Valve: Adjusts medium flow rate, pressure, etc., including throttle valves and pressure - reducing valves.

- Steam Trap: Also called a steam trap or drain valve. It automatically discharges condensate water, air, and non - condensable gases while preventing steam leakage.

How Valves Work?

Here, we've selected several of these valves and will briefly introduce their working principles.

The Working Principle of Ball Valve

The working principle of a ball valve is as follows: A ball valve uses a ball with a circular through - hole as the opening and closing part. When it's open, the circular through - hole of the ball aligns with the axis of the pipeline. This allows the medium to flow through smoothly without any obstruction, just like the pipeline is a straight, unblocked tube. When it needs to be closed, the ball is rotated. As a result, the solid part of the ball blocks the pipeline passage, stopping the flow of the medium. The tight seal between the ball and the valve seat prevents the medium from leaking. Moreover, you can rotate the ball easily through an operating rod or an actuator. This makes the operation convenient, enabling quick opening and closing of the valve.

The Working Principle of Butterfly Valve

The working principle of a butterfly valve is as follows:

A butterfly valve mainly consists of a valve body, a disc (the butterfly plate), a valve stem, and a drive device. The disc is a circular - shaped part located inside the valve body. In the open state, the disc is parallel to the fluid flow direction, almost lying flat against one side of the valve body. At this time, the fluid can flow smoothly through the pipeline with relatively low resistance. When it's time to close the valve, the drive device rotates the valve stem. The valve stem then drives the disc to rotate around its axis. As the disc rotates, it gradually becomes perpendicular to the fluid flow direction until it completely blocks the fluid passage, thus closing the pipeline and cutting off the fluid flow. During the rotation of the disc, it can stop at different angles according to actual needs. This allows for the regulation of the fluid flow rate, enabling the fluid to pass through the pipeline at different speeds, serving the function of flow control.

The Working Principle of Gate Valve

The working principle of a gate valve mainly relies on the relative movement between the gate plate and the valve seat to control the flow and cut - off of fluid, as follows:

Opening Process

The working principle of a gate valve mainly relies on the relative movement between the gate plate and the valve seat to control the flow and cut - off of fluid, as follows:

Opening Process

When closing the gate valve, operate the driving device to make the valve stem move downward, driving the gate plate to descend. The gate plate gradually approaches the valve seat until the gate plate closely fits onto the valve seat, completely blocking the passage and preventing the fluid from passing through, achieving the purpose of closing the pipeline.

Flow Regulation

When the gate plate is in a semi - open and semi - closed state, the size of the gap between the gate plate and the valve seat determines the amount of fluid passing through, which can achieve a certain degree of flow regulation. However, compared with dedicated control valves, gate valves are relatively poor in terms of flow regulation accuracy and stability. Generally, they are not recommended for occasions with high requirements for flow regulation accuracy.

Valve Comparison

There are many types of valves. Now, let's briefly take a look at the advantages, disadvantages, and comparisons of the following types of valves.

The Advantages and Disadvantages of Ball Valve

Advantages

- Small flow resistance: the channel is smooth when opening, the advantage of large-diameter pipeline is obvious, and it can reduce energy consumption.

- Fast switching: it can be fully opened or fully closed by rotating 90 degrees, convenient operation and quick response.

- Good sealing: the sealing surface is made of various materials, close fitting and strong anti-leakage ability.

- Simple structure: mainly composed of valve body, ball, valve stem and driving device, low manufacturing and maintenance costs.

- Wide range: applicable to water, oil, gas and corrosive media, can work under different temperature and pressure conditions.

Disadvantages

- Difficult throttling: difficult to accurately control the small flow when the flow is adjusted.

- Easy to wear: frequent opening and closing or transportation of impurity-containing media, the sealing surface is easily damaged, and affecting life.

- Weak at high temperature: the material is easily deformed at high temperature, and the sealing performance and operation flexibility will be reduced.

- Pressure loss: small opening degree, the fluid through the larger pressure loss, affecting the efficiency of the system.

The Advantages and Disadvantages of Butterfly Valves

Advantages

- Compact structure: small volume, light weight, occupies little space, easy installation and maintenance, suitable for limited space.

- Light operation: small opening and closing torque, labor-saving operation, fast opening and closing, high working efficiency.

- Good adjustability: the butterfly plate can control the flow better through different opening angles.

- Lower cost: simple manufacturing process, low material cost, and affordable price.

- Good sealing: reasonable design sealing, can effectively prevent leakage.

Disadvantages

- Seal limitation: high temperature, high pressure or medium abrasive, the seal is easy to decline to leakage.

- Large flow resistance: when fully open, the butterfly plate still obstructs the fluid, and the flow resistance is larger than that of ball valves.

- Pressure limitation: applicable to medium and low pressure, under high pressure, the butterfly plate and valve body are easy to be deformed, affecting the performance and life.

- Easy to generate water hammer: when closing quickly, the sudden change of fluid pressure in the pipeline may damage the pipeline system.

The Advantages and Disadvantages of Gate Valve

Advantages

- Small flow resistance: when fully open, the channel is nearly straight through, low water resistance coefficient, suitable for large-diameter pipelines, which can reduce the energy consumption of the system.

- Excellent sealing: the sealing surface of the gate and the valve seat is closely fitted, and the leakage prevention effect is good under normal working conditions.

- Strong applicability: suitable for water, steam, oil and other media, can work under different temperature and pressure conditions.

- Flexible installation: opening and closing are not affected by the flow direction of the medium, which is convenient for various pipeline arrangements.

- Full open without obstruction: the gate is fully open without obstructing the fluid, guaranteeing the smooth flow of fluid in the pipeline.

Disadvantages

- Slow opening and closing: gate lifting and lowering to realize the opening and closing, the process is complex, time-consuming, not applicable to the need for rapid opening and closing of the scene.

- Difficult to regulate: mainly used to cut off or connect the fluid, flow regulation ability is poor, generally only as a stop valve.

- Complex structure: composed of valve body, valve cover and other components, many parts, high manufacturing and maintenance costs, difficult.

- Occupies a large area: large structural dimensions, large caliber requires a large installation space, increasing the difficulty of pipeline layout.

- Easy to jam: long-term use, especially in the media containing impurities or particles, the gate and seat easy to jam, affecting the normal use.

The Top10 Valve Brand

Finally, let's share some of the world's top 10 valve brands that are widely recognized.

- Emerson: Founded in the United States in 1890, it is a leading player in the industrial valve field. It offers a wide range of products including ball valves, butterfly valves, control valves, etc., which are widely used in industries such as oil, chemical, power generation, and water management. It attaches great importance to R & D and leads in valve diagnosis and control system technologies.

- Flowserve: An American brand with a history dating back to 1790. It provides various valves like control valves, ball valves, gate valves, etc., as well as fluid motion and control solutions. Its production is rigorous, and products are of high quality, suitable for extreme working conditions.

- AVK Group: Founded in Denmark in 1941, it focuses on the manufacture of valves for water and wastewater management. Its products are used in municipal water supply, irrigation, industry, etc. They are durable, water - saving, and environmentally friendly.

- KSB Group: Originating from Germany in 1871, it is a well - known manufacturer of valves and pumps. It produces globe valves, gate valves, butterfly valves, etc. with precise craftsmanship, strict quality control, and strong product sustainability.

- Kitz: A Japanese company founded in 1951, renowned for integrating innovative technology with handicraft. It provides valves made of materials like brass, bronze, and stainless steel, which are widely applied in residential plumbing and industrial fields.

- IMI: A British enterprise, standing out with innovative fluid control technology. Its products include drive valves, safety valves, control valves, etc., used in industries such as power generation and life sciences, effectively controlling fluids and reducing energy consumption.

- VELAN: Founded in Canada in 1950, it manufactures high - performance valves for the oil, gas, and nuclear industries, such as steam traps, forged gate valves, etc., with strict quality standards.

- Siemens: Founded in Germany in 1847, this comprehensive giant has advanced technology and rich experience in the valve field. Its products are of excellent performance and high reliability, with a wide range of applications.

- Honeywell: An American multinational company founded in 1895. Its valves cover industrial, commercial, and residential fields. With advanced technology and high - quality after - sales service, it has a place in the market.

- Parker: A long - established British brand founded in 1751, it is a leading manufacturer of fluid control equipment with a rich valve product line and professional technical support

Summary

Although small, valves are indispensable in industry, urban construction, daily life and other scenes. It is the key to the stable operation of fluid systems, connecting equipment and pipelines. From the daily water supply and power supply to complex chemical production, the rational selection of valves is related to production efficiency, resource utilization and safety and environmental protection. With the development of technology, the performance of valves is constantly improving, and we look forward to innovative valves in the future to further optimize fluid control and help the development of various industries.