Difference Between T-Type and L-Type 3-Way Ball Valves

What is a 3-Way Ball Valve?

When it comes to controlling the flow of fluids or gases in industrial systems, the 3-way ball valve is one of the most commonly used valves.

The 3-way ball valve offers versatile flow control, allowing the user to easily divert or mix flow depending on the valve configuration. The two most popular configurations for 3-way ball valves are T-Type and L-Type.

What is a T-Type 3-Way Ball Valve?

The T-Type 3-Way Ball Valve features three ports on the ball, arranged in a "T" shape. This allows the valve to mix or divert flow between different paths. The design of the T-Type Ball Valve makes it ideal for applications that require the ability to control and combine flow from multiple sources or send flow to different destinations.

Key Features of T-Type Ball Valve:

T-Shaped Three Ports: This configuration enables mixing or diverting of fluids.

Flow Path Versatility: The valve can connect all three ports (mixing) or allow two ports to be closed and the third port to be open (diverting).

Compact Design: Despite its versatility, the T-Type Ball Valve is compact and effective in installations with limited space.

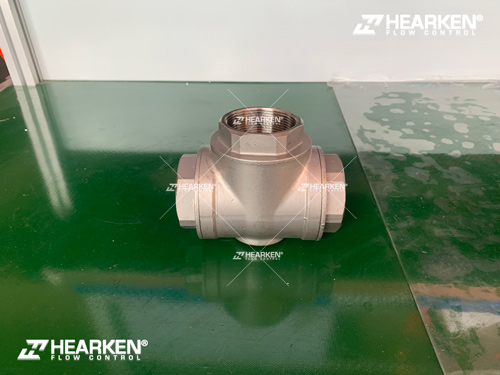

What is an L-type 3-way ball valve?

L-type 3-way ball valves feature three ports on the ball, arranged in an "L" shape. In this configuration, two ports are connected in a straight line, and the third port is perpendicular to the other two ports. L-type valves are generally used to divert flow between two independent paths, but can also be used for mixing in some applications.

Main features of L-type ball valves:

L-shaped three ports: The L-shaped connection generally allows diversion between two flow paths.

Mainly used for diversion: L-type valves are ideal for directing flow between two systems.

Suitable for basic flow control: Used in simple applications where two paths need to be mixed or switched.

T-type vs. L-type 3-way ball valves: Main differences

1. Flow control function

T-type valve: Provides mixing and diverting functions. It can mix flows from two different sources into one output, or divert a single flow into multiple outputs.

L-type valve: Mainly used to divert flow from one source to two different destinations, with less flexibility in mixing flows.

2. Valve Design

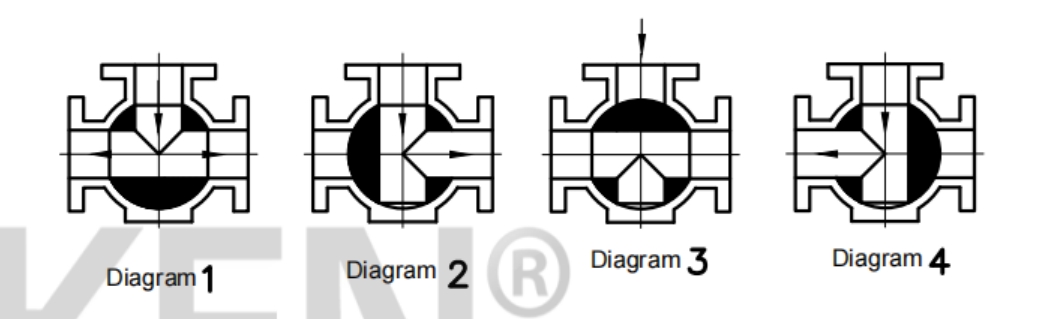

T-Valve: The ball is arranged in a "T" shape with three ports. This configuration allows the valve to manage more complex flow paths, allowing for both mixing and diversion in a single valve.

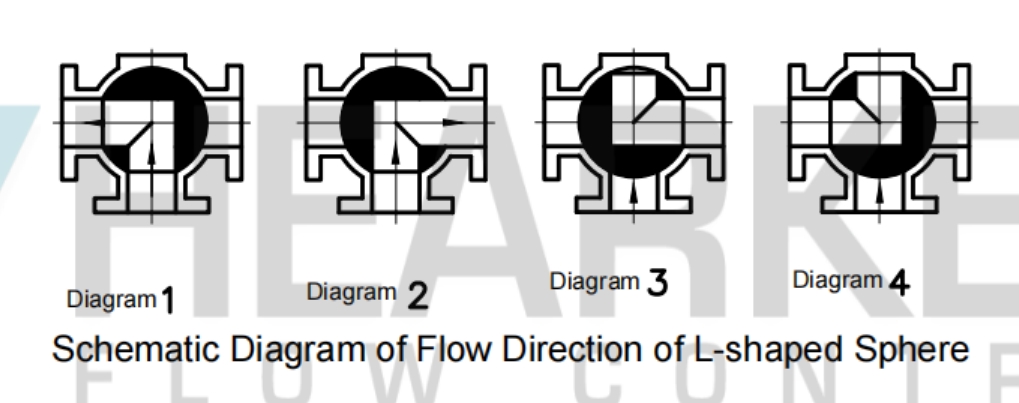

L-Valve: The ball in the L-Valve is in an "L" shape with two ports arranged in line and one port arranged vertically. It is better suited for simpler flow control applications.

3. Applications

T-Valve: Suitable for systems that require mixing of fluids (e.g., mixing two different fluids before feeding them into a single system) or systems that require transferring fluids between multiple destinations.

L-Valve: Best suited for systems that only require transferring fluids between two paths, such as dividing or directing fluids into two branches.

T-Type 3-Way Ball Valve VS L-Type 3-Way Ball Valve Advantages and Disadvantages

What are the advantages of a T-Type 3-Way Ball Valve?

Versatile flow control: Can mix or divert flows, providing flexibility for more complex systems.

Space saving: Compact design, suitable for systems with limited space.

Precise control: Provides greater precision when controlling the flow of multiple media streams.

What are the disadvantages of a T-Type 3-Way Ball Valve?

More complex design: The ability to mix or divert flows increases the complexity of the valve, which can lead to higher maintenance requirements.

Cost: Typically more expensive than an L-Type valve due to its increased functionality and design complexity.

What are the advantages of an L-Type 3-Way Ball Valve?

Simple: Great for simple flow diversion applications, making it easier to install and maintain.

Cost-effective: Typically more affordable than a T-Type valve due to its simpler design and functionality.

Reliability: Since it is primarily used to divert flows, it has fewer moving parts, resulting in greater durability.

What are the disadvantages of an L-Type 3-Way Ball Valve?

Limited flow control: L-Type valves cannot mix flows; they are only used to divert flow between two paths.

Less flexibility: L-type valves are not suitable for applications that require mixing or combining flows from multiple sources.

Common applications of T-type and L-type ball valves

- T-type three-way ball valve applications

Due to its unique fluid control capabilities, T-type three-way ball valves are widely used in a variety of scenarios that require mixing or multi-directional flow control. Here are some typical applications:

Hot and cold water mixing: Precisely control water temperature in the piping system to ensure stable system operation.

Industrial process control: Precise flow regulation and mixing between multiple fluid paths to meet the needs of various industrial processes.

Chemical processing: Used to mix different chemicals in specific proportions to ensure uniform mixing and meet production requirements.

- L-type three-way ball valve applications

L-type three-way ball valves are particularly suitable for situations that require basic flow distribution or simple switching due to their simple design and reliable performance. Common applications include:

Industrial processes: Used to accurately control the direction of chemical flow to ensure fluid scheduling in production processes.

Irrigation systems: Switch water flows between water sources or water areas to optimize irrigation efficiency and improve resource utilization.

HVAC Systems: In HVAC systems, L-type ball valves are used to effectively direct the flow of coolant, ensuring smooth operation of temperature control systems.

Conclusion

T-type and L-type three-way ball valves each offer unique advantages depending on your flow control needs. T-type valves are ideal for mixing and diverting, providing greater flexibility, but with higher cost and complexity.

In contrast, L-type valves are well suited for diverting applications and are simpler and more cost-effective for basic flow control systems. Choosing the right valve depends on your specific requirements, such as whether you need to mix or simply divert.