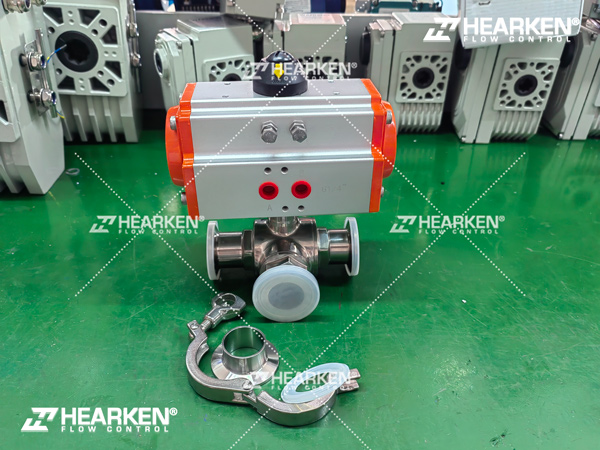

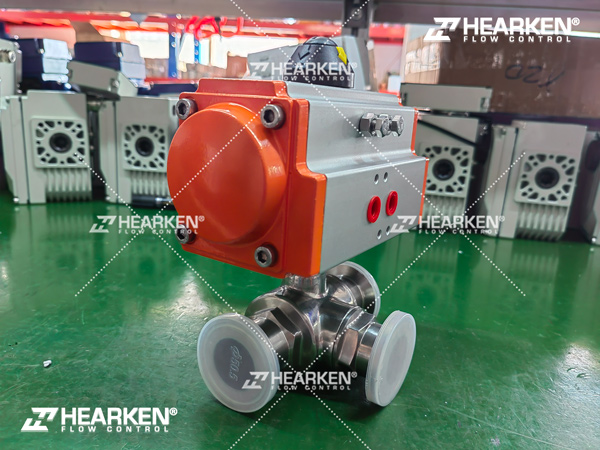

Introduction to Sanitary Ball Valves

Sanitary Ball Valves is commonly used in industries with high hygiene requirements, such as food, beverage, pharmaceutical, cosmetics, etc., and is designed and manufactured in accordance with relevant hygiene standards to ensure cleanliness and safety during fluid transportation.

The Working Principle of Sanitary Ball Valves

Sanitary ball valve mainly through the ball rotation to achieve fluid turn-off and flow control, as follows:

Basic Opening and Closing Principle:

A ball with a round through hole in the ball valve is located between the flange of the valve body and the seat. When closed, the ball through the hole is perpendicular to the valve body channel to block the fluid; When opened, operate the stem so that the ball rotates 90 degrees, the through hole is aligned with the channel, and the fluid can pass through.

Flow Regulation Principle

Control the ball to rotate to the appropriate Angle, change the through hole and channel connectivity area, you can adjust the flow. For example, in the process that requires precise flow control, the sphere is turned to 45 degrees, etc., to reduce the connected area and reduce the flow through.

Power Drive Principle

1. Manual: The manual ball valve drives the stem by rotating the hand wheel. Turn the handwheel counterclockwise when opening, the valve stem rises, the bottom angular plane makes the ball release the seat, continue to lift, the valve stem and the guide pin make the ball rotate to full open; When closing, turn the hand wheel clockwise, the valve stem drops to make the ball rotate, and when closing, the ball has been rotated 90 degrees without contact, the last few turns of the handwheel, the bottom of the valve stem pressure the ball, so that it compresses the valve seat to achieve seal.

2. Pneumatic: pneumatic ball valve with pneumatic actuator. Connect the open signal, compressed air into the cylinder to push the piston, and the piston drives the push rod to rotate the ball to the open position; When the close signal is received, the piston moves in reverse and the rotating ball interrupts the fluid channel.

3. Electric: Electric ball valve driven by electric actuator. With the control signal, the motor runs through the transmission device to drive the valve stem and the ball to rotate, to realize the valve opening and closing and flow regulation, which is often used in the production system with a high degree of automation, and can be controlled remotely and accurately.

Sealing Principle

The ball is closely matched with the seat. High-performance sealing materials such as polytetrafluoroethylene are commonly used for the valve seat, which has low friction coefficient, good chemical stability and elasticity. When the valve is closed, the ball compresses the seat under the action of the valve stem to form a sealing surface, which can also be effectively leak-proof for long-term use.

The Material Characteristics of Sanitary Ball Valve

Valve body, Disc and Stem

316L stainless steel, low carbon content, strong corrosion resistance, can maintain structural stability in harsh chemical environments. The surface is often polished with high precision to reduce medium residue and bacterial growth.

Sealing Element

Generally use food grade, pharmaceutical grade silicone rubber, EPDM rubber or polytetrafluoroethylene (PTFE). Silicone rubber and EPDM rubber have good elasticity, non-toxic and tasteless, and good sealing effect; PTFE has low friction coefficient, high chemical stability, high and low temperature resistance, and can adapt to the sealing requirements under various working conditions.

Main Application Areas

Sanitary ball valves are widely used in industries with high requirements for hygiene and fluid control due to their good sealing, no dead angle and easy cleaning.

Food and Drink

During the production of dairy products, it is used in milk transportation, ingredient addition and other links to avoid microbial contamination. In beverage production, from raw materials to filling processes, it can accurately control fluids to prevent cross contamination and ensure product quality.Introduction to Sanitary Ball Valves

Sanitary Ball Valves is commonly used in industries with high hygiene requirements, such as food, beverage, pharmaceutical, cosmetics, etc., and is designed and manufactured in accordance with relevant hygiene standards to ensure cleanliness and safety during fluid transportation.

Pharmaceutical

In API production, you can control the delivery of chemical raw materials and solvents to ensure purity. In preparation production, you can control media such as purified water and drug solutions to meet the high cleanliness requirements of drugs.

- Bioengineering

In the fermentation process, it is used in the feeding and ventilation of the fermentation tank to maintain a sterile environment and improve the fermentation efficiency. During cell culture, it controls the delivery of the culture medium to provide stable sterile conditions for cell growth.

Cosmetics

When storing and transporting raw materials, prevent oils, spices and other raw materials from being contaminated; during product filling, accurately control the filling volume, ensure the cleanliness of the equipment, and ensure the quality and safety of cosmetics.

Fine Chemicals

Produce high-end chemicals, control high-purity raw materials and intermediates, and ensure product performance; in chemical experiments and R&D, it is used for small devices and pilot equipment to meet hygiene and precision requirements.

Maintenance Points

Daily Maintenance

Appearance cleaning: Wipe the outer surface of the sanitary ball valve regularly with a soft damp cloth to remove dust and oil stains so that surface corrosion and scratches can be detected in time.

Check the connection parts: Check whether the connecting bolts and nuts are loose and tighten them in time. Check the flange gasket and other seals. If they are damaged or aged, they need to be replaced in time.

Operation flexibility check: Check whether the valve is opened and closed manually during the equipment operation interval or regularly to check whether it is smooth. If there is any jamming, troubleshoot it in time.

Regular Maintenance

Valve core inspection: Disassemble the valve regularly to check whether the valve core has wear, corrosion, or scratches. If there is damage that affects the sealing performance, it needs to be repaired or replaced in time.

Valve stem maintenance: Check the surface finish and straightness of the valve stem to check for bending, deformation, and corrosion. Apply special grease after cleaning to ensure that it can be raised and lowered and rotated flexibly.

Seal replacement: According to the frequency of use and working conditions, seals such as sealing rings should be replaced regularly to ensure good sealing performance of the valve.

Clean the internal channel: Rinse the inside of the valve with clean water or special cleaning fluid at a certain pressure to remove dirt and impurities. Soft tools can be used to clean difficult-to-clean areas, and be careful to avoid damaging the inner surface.

Pressure test: Use professional equipment regularly to perform pressure tests on the valve according to standards to ensure that it operates safely and reliably within the working pressure range.

Summarize

Sanitary ball Valve is best for rapid on/off control,the diaphragm valve offers more precise regulation and is suitable for systems with complex flow requirements.

FAQ:The Difference between Sanitary Ball Valves and Ordinary Ball Valves

Design and Manufacture

1. Sanitary ball valve: To meet strict hygiene requirements, it adopts a full-diameter, no-dead-angle design, and a small gap between the ball and the valve seat. The manufacturing process is highly precise and the surface is highly polished

2. Ordinary ball valve: The design focuses on general fluid control, the structure is simple, and there may be dead angles or rough areas in the flow channel. Low manufacturing precision and surface treatment requirements

Material Selection

1. Sanitary ball valve: The valve body, valve core, and valve stem are mostly made of high-grade stainless steel such as 316L, which has strong corrosion resistance. The seals are made of silicone rubber, polytetrafluoroethylene, etc. that meet food and medical standards, which are non-toxic and odorless to avoid contaminating the medium.

2. Ordinary ball valve: The valve body is usually made of ordinary carbon steel, cast iron or 304 stainless steel, which is suitable for general corrosive media. The seals are ordinary rubber or plastic, and the hygienic performance is inferior to that of sanitary ball valves.

Application Areas

1. Sanitary ball valve: used in industries with extremely high hygiene requirements such as food, pharmaceuticals, and cosmetics to control high-purity, easily contaminated fluids to ensure production hygiene and product quality safety.

2. Ordinary ball valve: used in industrial and civil fields such as petroleum, chemical, and construction to control conventional fluids such as water and steam, with low hygiene requirements.

Inspection and Certification

1. Sanitary ball valve: needs to pass strict sanitation certification such as 3A, FDA, GMP, etc., and the testing items cover surface roughness, cleanliness, microorganisms, etc. to prevent contamination of the medium.

2. Ordinary ball valve: only needs to pass conventional pressure and sealing performance tests and meet industrial standards, and has fewer sanitation testing requirements.