What is the Difference Between Single-Acting and Double-Acting Positioners?

What is a single-acting and double acting positioner?

Understanding Single-Acting Positioners

Definition: Single-acting positioners control pneumatic actuators by allowing air to enter only one side of the actuator.

Application: These positioners rely on a spring return mechanism to bring the actuator back to its default position and are commonly used in applications where simplicity and cost-effectiveness are priorities.

Understanding Double-Acting Positioners

Definition: Double-acting positioners control actuators by allowing air to flow to both sides of the actuator, enabling precise bidirectional movement.

Application: Without relying on a spring, double-acting positioners provide better stability and control, making them ideal for heavy-duty applications and situations where precise positioning is required.

Key Differences Between Single-Acting and Double-Acting Positioners

1. Control Mechanism

Single-acting positioners: Use a spring to return to the default position when air pressure is removed, making control simpler and straightforward.

Double-acting positioners: Rely on air pressure on both sides of the actuator, providing smoother and more flexible bidirectional control without a spring.

2. Cost and Maintenance

Single-acting positioners: Typically more affordable and require less maintenance, making them suitable for applications with basic positioning needs.

Double-acting positioners: Generally more expensive but provide superior control, making them a valuable investment for high-precision applications.

3. Applications and Preferences

Single-acting positioners: Ideal for simpler, low-cost applications where precision is not a primary concern but budget and ease of use are important.

Double-acting positioners: Ideal for heavy-duty applications where precise control and stability are essential. Suitable for industries that require enhanced performance and accuracy.

How Can a Positioner Be Changed from Double-Acting to Single-Acting?

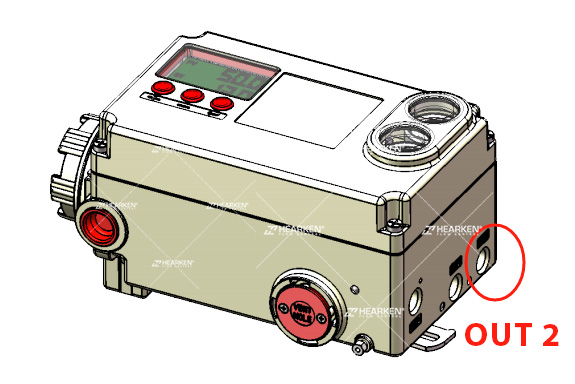

Changing a positioner from double-acting to single-acting is straightforward. Simply block the port labeled "Out 2" and the positioner will operate as a single acting unit.

Can a Positioner Be Changed from Single-Acting to Double-Acting?

No, a single-acting positioner cannot be modified to function as a double-acting one.

Conclusion

When choosing between single-acting and double-acting positioners, consider your application needs, budget, and control requirements. Double-acting positioners offer high precision, while single-acting models provide simplicity and cost savings for less demanding uses.